What Building Materials are Used in Construction?

There are many types of building materials used in construction such as Concrete, Steel, Wood and Masonry. Each material has different properties such as weight, strength, durability and cost which makes it suitable for certain types of applications. The choice of materials for construction is based on cost and effectiveness to resisting the loads and stresses acting on the structure. As a structural engineer, I work with my clients to decide on the type of materials used in each project depending on the size and use of the building.The manufacturing of building materials is a well established and standardized industry capable of providing a reliable supply of high-quality materials for our structures.The production of structural-grade building materials is subject to quality control procedures that involve inspection and testing according to national standards and scientific testing methods.

Part of the structural engineer’s responsibilities is to prepare the project specifications including all building materials and applicable standards and provision to comply with. This is a crucial part of any project to specify the quality and properties of materials to be used.

Building materials can generally be divided into two categories: Natural building materials such as stone and wood, and Man-made building materials such as concrete and steel. Both categories usually require a certain level of preparation or treatment before the use in a structural application. Below is the list of materials I used the most in engineering consulting projects.

Concrete

\

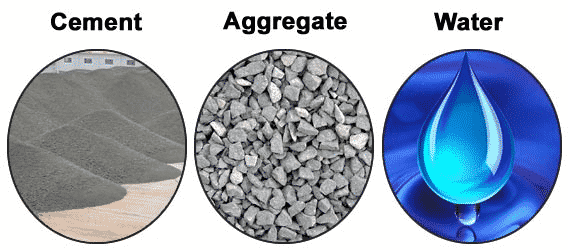

Concrete is a composite material made from mixing cement, aggregates such as sand and crushed stone and water. The properties of concrete depend on the ratios used in the mix design. Therefore, it’s a standard practice for concrete suppliers to provide material properties and test results for each concrete patch.

Fresh concrete can be poured into form works to take any shape or form and takes time to harden into a stone-like material. It takes up to 7 days for concrete to reach the majority of its strength and will need special attention to curing to avoid cracking or reduction in capacity. Concrete is very versatile and is my go to material for applications that require a combination of strength and durability. For example, concrete is an excellent material for building foundations where the weight of the structure meets the ground. This requires strength to carry the load and also durability to withstand the contact with the surrounding soil.

Concrete is very strong when exposed to compression stresses however, it’s brittle and has limited tensile strength. Combined with steel rebar, reinforced concrete is stronger and more suitable for a wide range of structures such as tall multi-story buildings, bridges, roads, tunnels and so many other applications.

Steel

Steel is one of the strongest building materials available with excellent strength capacity in both tension and compression. Because of its high strength-to-weight ratio, it is ideal for structural framework of tall buildings and large industrial facilities. Structural steel is available in standard shapes such are angles, I beams and C-channels. These shapes can be welded together or connected using high-strength bolts to build structures capable of resisting large forces and deformations.

Steel is a relatively expensive building material so it is the structural engineer’s responsibility to choose economic sizes and shapes according to the actual loads on the building to avoid overdesign. Because of the the higher cost of steel, I often get questions from our clients asking if there is a way to reduce the weight and size of some of steel members in the structure. This can be done if the loads can be reduced on the members and/or additional vertical supports can be introduced. The installation of steel is less time consuming compared to concrete and can be installed in any type of environment.

Wood

Wood has been used as a construction material for thousands of years and if properly maintained can last for hundred of years. It is a readily available and economically feasible natural resource with a light weight and highly machinable properties. It also provides good insulation from the cold which makes it an excellent building material for homes and residential buildings.

Wood pieces used in construction are machine-planed and sawn into certain dimensional specifications. Dimensional lumber comes in widely available sections such as 2”x4”, 2”x6”, etc. This is commonly used in the construction of walls and floors. Believe it or not, a 2”x4” is actually 1 ½” wide x 3 ½” high. Wood that comes in larger dimensions are referred to as timber or beams and are commonly used to construct the frames of large structures such as bridges and multi-story buildings. Engineered wood is another type of wood used in construction that consist of various forms of wood glued together to form a composite material suitable for specific construction applications. Examples of engineered wood is glued laminated wood (glulam), plywood and fiberboard.

Because of its light weight, wood is not the most suitable construction material to support heavier loads and not ideal for long spans. Wood is rarely used for foundations and basement walls, as it needs to be pressure treated because of its contact with soil/moisture which can be fairly expensive. In a wood framed house, the foundations and basement walls are usually constructed with reinforced concrete.

Masonry

Masonry construction is using individual units to build structures that are usually uses mortar to bound the units together. The most common material I use in the design of masonry structures is concrete block, with vertical steel reinforcing if required. Masonry is strong in resisting compression loads/stresses which makes it ideal to use for the construction of load bearing walls. Other masonry materials include brick, stone and glass block. Masonry is a highly durable and fire resistant material, however it can be sensitive to mortar and workmanship quality.

There has been an increase in the use of masonry as load bearing walls for the design of multi-story buildings in my office. The structural system typically consists of concrete floors supported on a combination of masonry and reinforced concrete walls depending on the number of floors and amount of load on the walls. Masonry walls with windows or openings need horizontal beams or lintels to span the weight of the wall above across the opening. Masonry is not as accommodating to large openings in walls as concrete or steel framing is, but can be an economical choice if the framing and opening sizes are reasonable and length of wall segments are not too short.

Load bearing masonry walls can be stacked up on top of one another to build multi-story buildings. The load on the first floor masonry wall is the accumulation of all the weight of the floors above it. Therefore, the bottom floor wall must be stronger than the upper floor walls. This can be achieved by reinforcing the voids in the bottom masonry walls with steel bars and concrete grout. More steel bars closer spacing of grouted cores equals stronger masonry walls. If a load bearing masonry wall does not extend all the way down to the foundation because of required openings such as parkade drive aisles, large concrete or steel transfer beams are required to support the wall above the opening.

There is lots more that can be covered on the topic of construction materials, but hopefully this gives you a good understanding of each of the major materials and the applications that are best suited for each of them. If you have any questions on any of these materials, feel free to leave them in the comment section below.

ABU DHABI, UAE

Head Office:

Musaffah Al BEES 2 ST M14 Building 26 | P.O. Box 92048

025833718 | [email protected]